From KUT:

Winter is coming and power plants across Texas are in a rush to “winterize.” That’s a word you’ve probably heard a lot since February’s big blackout; winterizing natural gas power plants to withstand the cold is crucial to guarding against future grid failures.

It’s so important that the state’s Public Utility Commission just passed new rules requiring power plants to do it. But, for all that, you may not know what winterization actually looks like.

Well, look no further. KUT recently toured a natural gas power plant in Midlothian, Texas, to figure it out.

Transmission lines stretch out from the Vistra power plant in Midlothian. Gabriel C. Pérez

The plant

You know you’re approaching the Midlothian power plant when you see the transmission lines. They stretch out from it, shooting off in different directions over the flat North Texas countryside. Follow those lines down bumpy back roads and you arrive at the plant itself.

It is a six-unit operation. That means there are six electric generators here. Each one is a mini power plant in its own right, with its own turbines and stacks to vent out emissions. These units stand in a row in a fenced-off field, along with transmission and gas infrastructure, and big water tanks. When they’re all up and running, they generate enough power for 330,000 homes in times of peak energy demand like last February.

In many ways the Midlothian plant, owned by Vistra Corp., is representative of most gas plants in the state. It is a combined-cycle plant, requiring water, air and (of course) gas to generate electricity. These ingredients move through pipes to spin turbines, turn valves and other components. They combust, boil, pressurize and evaporate, and they need to keep flowing for power to come out of the plant.

The problem

That didn’t happen last February. About 50% of the state’s natural gas fleet stopped working in the cold. And, walking around the Midlothian plant, it’s easy to see how. Much of the plant feels out in the open. The tanks, valves, power lines, pipes and control panels covering the generators seem exposed.

The tanks, valves, power lines, pipes and control panels covering the generators are all out in the open, exposed to the weather.

Gabriel C. Pérez

Plant Manager Curt Terry says plants don’t look like this in colder parts of the world.

“Everything you’re seeing would be inside an enclosure,” he says, “which is one of the challenges in Texas, because we’ve got to battle the heat more than the cold.”

That, in a nutshell, is what “winterizing” is. You take a Texas power plant designed to withstand summer heat, and make sure those three ingredients — air, water and gas — keep moving so the plant can make electricity in the cold, too.

Dry air

Many people may not know how essential clean dry air is to the production of electricity. Gas plants need air to run turbines to generate power, and a lot of the moving parts at these plants — the valves and actuators — are controlled with pressurized air.

“If those lines were to freeze going to those valves and actuators you may not be able to get a valve to control itself, which could ultimately cause a trip or, in this case, a forced outage,” Terry says, pointing at some heavily insulated pipes.

He says keeping the pipes from freezing starts with the air compressors that sit outside the generation units. At the Midlothian plant those compressors include humidity monitors and air dryers to keep moisture out. Less moisture in the air means less possibility of freezing in the pipes.

Gabriel C. Pérez

Pipes are wrapped with insulation to protect them from the cold.

To protect the compressors and other exposed machinery from the elements, plant operators have also built little metal shelters and windbreaks around them. These are simple corrugated metal walls and sheds, sometimes with heaters in them.

On warm days, like the day KUT visited, the shelters can be opened up to keep things cool. In the winter, they can be closed off.

Running water

Pipes snake all around these generating units, carrying all sorts of things that could freeze, including water.

Most of the pipes seem insulated, but in extreme cold that won’t cut it. So, at the Midlothian plant operators have buried heating cables within the insulation. This is a technology called “heat tracing” that keeps the lines warm when temperatures outside drop below a certain level.

Terry says there are about 12 miles of heat tracing installed in this plant. Other plants across the state are getting it installed in preparation for winter. If the heat-tracing lines malfunction or the pipe temperatures drop, sensors go off to warn plant operators so they can try to warm things back up.

Plant Manager Curt Terry shows heat-tracing wires used to warm pipes.

Gabriel C. Pérez

“We also have portable heaters at our disposal. We have portable line-thawing machines,” Terry says. “I mean there’s a tremendous amount outside of what we’re showing you.”

But then, he does show us.

In a big warehouse, he points out shelves and shelves of extra just-in-case equipment like space heaters. After last winter’s storm, this warehouse has become a regional storage hub for gear that might come in handy in the next storm.

Reliable gas

All this stuff — the insulation, the heat tracing, the temperature monitors, windbreaks and air dryers — all comprise what people call “winterization.” Power plants around the state are currently installing or upgrading these things in preparation for the cold. At the Midlothian plant, very little of this is new, Terry says; unlike many other plants, this one winterized after the last big blackout in 2011.

But that still didn’t keep things running.

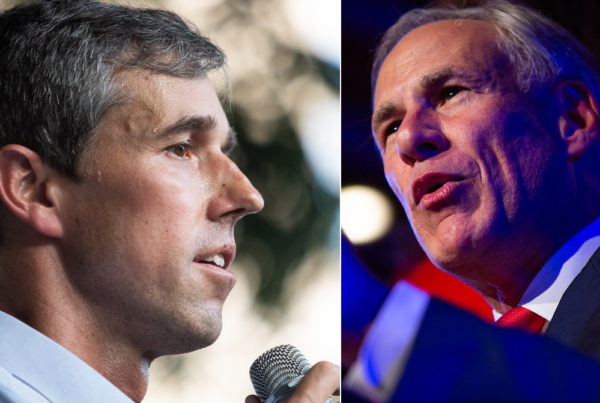

The plant could operate only at 30% capacity at certain times during the February freeze because of limited gas supply.

Gabriel C. Pérez

That’s the reason Vista Corp. invited reporters here. Even though nothing froze or broke in February, the plant could only operate at 30% capacity at certain times. The reason for that, Vista says, was limited gas supply.

“This is where we were basically handicapped during the winter event Uri,” Terry says, pointing to the place where gas runs from the statewide supply system into the plant.

The gas, he says, just stopped flowing. That’s something the people here cannot control.

‘Your rule proposal sucks.’

This reliability of the state’s gas supply has become a big sticking point for Texas leaders in the aftermath of the blackout. At a state Senate hearing earlier this fall, lawmakers railed at Texas oil and gas regulators over a loophole in their proposed rules that allows gas suppliers to opt out of winterizing.

In that hearing they also learned that the Railroad Commission of Texas — the agency that regulates oil and gas — had not yet inspected all the gas sites that stopped working in February’s storm.

“It sounds like you’re gonna miss this coming winter,” Republican state Sen. Donna Campbell said to Wei Wang, executive director of the commission.

“Well, our weatherization rule will not be adopted before this winter,” he conceded.

State Sen. Democrat John Whitmire was more pointed in his comments. “Your rule proposal sucks,” he said in reference to the winterization loophole.

So far, Texas oil and gas regulators appear defiant. The Railroad Commission says it is following the letter of the law by offering gas companies a way out of winterizing. The chair of the Railroad Commission recently lauded his team on the work it’s done.

Terry says the last thing he wants is a repeat of what he went through last February.

“When you got your team out here and they’re doing what they’ve been trained to do and they’re producing power and they’re basically being curtailed and held back I don’t think anybody wants to be in that position,” he says.

But as long as natural gas is unreliable in a storm, so, too, is the state’s electric grid.

Got a tip? Email Mose Buchele at mbuchele@kut.org. Follow him on Twitter @mosebuchele.