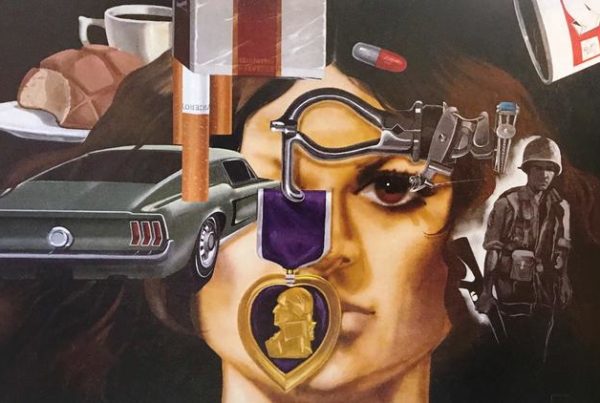

In the 1950s and ’60s, the idea that Texas would one day relinquish its position as the epicenter of the wool and mohair world must have felt unfathomable.

Raising sheep and goats was crucial to the state’s economy and culture. Land and herds were passed down for generations. The state’s sheep and goat industry even held an annual pageant to crown Miss Wool Texas.

Those days are gone though. Texas used to be home to over 10 million sheep and 4 million goats. Now there are less than a million of each. The industry built around them is smaller too. But it hasn’t disappeared.

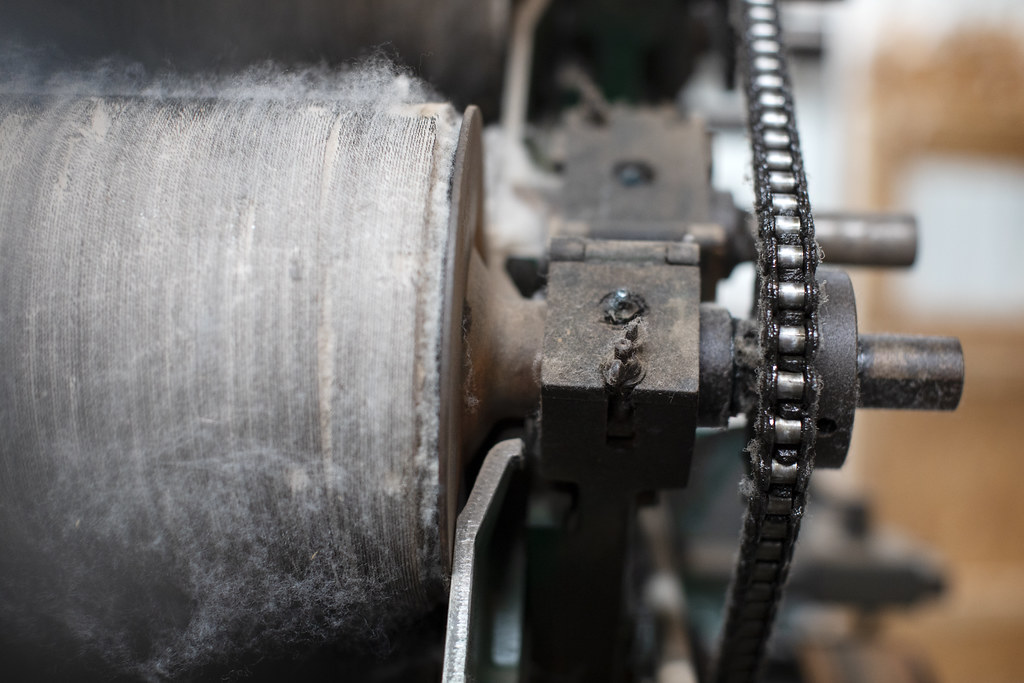

Part of what’s left of it is inside the Marathon Basin Wool Mill, about 40 miles south of Fort Stockton. Its owners, Seth and Bonnie Warnock, have deep roots in the Texas sheep business. The mill itself is a lonesome tan building in the West Texas desert. Inside, dozens of sacks filled with dirty wool sit on a concrete slab. Turning it into usable yarn can be a difficult, persnickety, and tedious task. On a cold day in late December, Seth showed reporters part of the process.

“It’s kinda loud and everything moves, so keep your hands to yourself,” he says while adjusting the gears of a spinner – a machine that converts wool into yarn.